Description:

This fried food centrifugal de-oiling machine is widely used for fried food and puffed food deoiling and also for fruit and vegetable dewatering after washing.

We have two kinds centrifugal de-oiling machine available:

1: Semi-automatic style, it needs people to pick up the barrel to discharge the items after deoiling and it was always used in small scale production line.

2: Fully automatic style: it can automatically discharge the items from the bottom after deoiling.

This style deoiling machine was always used in large scale production line.

Working Principle:

Our fried food centrifugal de-oiling machine adopts principle of centrifugal force, the barrel rotates in high speed, then the water or oil in the products will fly in high speed rotating.

Features:

1: This frying food deoiling machine is made of food grade SUS304 stainless steel, with the advatange of small size, low consumption, easy operation, labor and time saving

2: The dewatering or deoiling time can be set according to the raw material to satisfy different demand.

3: Smooth operation without shaking, safe to the operators and less damage to the machine itself

4: The de-oiling machine can be equipped with speed controller to adjust the speed of whirling basket according to your needs.

| Parameters of semi-automatic deoiling machine: | ||||

| Model | Dimension | Weight | Power | Capacity |

| LFTY-400 | 1000*500*700mm | 360kg | 1.1kw | 300kg/h |

| LFTY-500 | 1100*600*750mm | 450kg | 1.5kw | 400kg/h |

| LFTY-600 | 1200*700*750mm | 520kg | 2.2kw | 500kg/h |

| LFTY-800 | 1400*900*800mm | 680kg | 3kw | 700kg/h |

| Parameters of automatic bottom discharging type deoiling machine: | ||||

| Model | Dimension | Weight | Power | Capacity |

| LF-LTY-800 | 1250*1250*1550mm | 600kg | 1.5kw | 1000kg/h |

| LF-LTY-1000 | 1400*1400*1600mm | 800kg | 2.2kw | 1500kg/h |

1: All models can be customized according to your needs

2: Information on this website is subject to change, please contact us for more details.

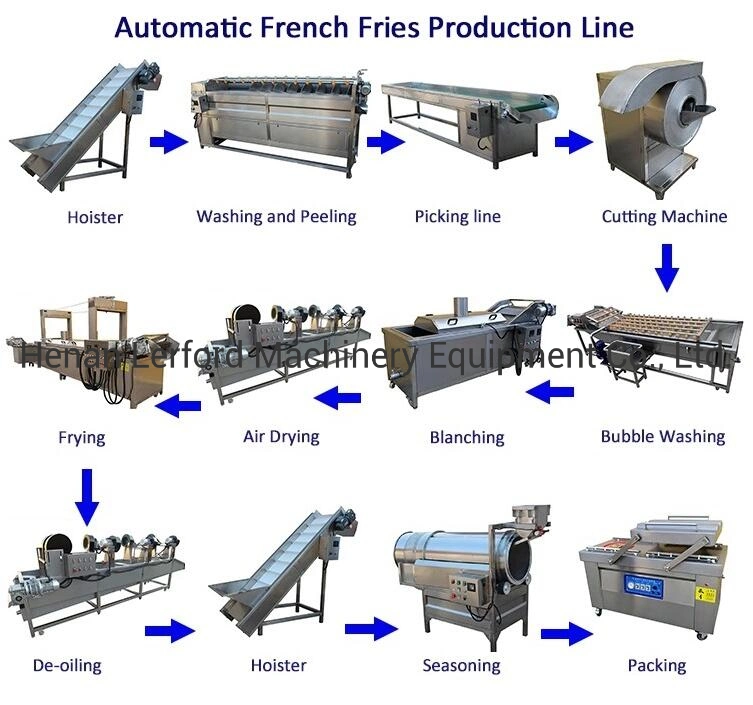

3: These frying food deoiling machine always work with other machines like frying, hoister or seasoning machine to combine a complete production line, following are some photos for your reference:

4.Our company have the full production line of automatic semi automatic french fries production line.