Wenzhou Yerong International Trading Co., Ltd provides a wide range of high quality equipment and service for printing and packaging industry, including post-press equipment such as flatbed automatic die cutter, hot foil stamping machine, folder gluer, paper guillotine, thermal laminator, flute laminator, slitter rewinder, paper sheeter, hard cover making machine, and label making machine such as flexo printing press, label die cutting machine, and flexible packaging equipment such as rotogravure printing machine, dry laminator, plastic bag making equipment, packing machine and other paper products machinery etc.

Production Introduction:

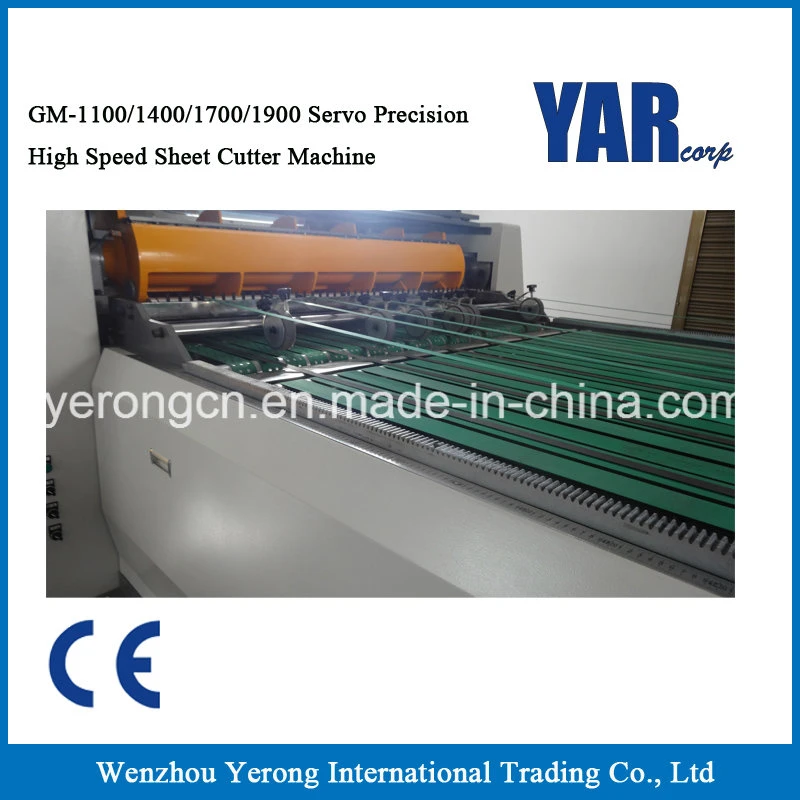

GM-1100/1400/1700/1900 Servo Precision High Speed Sheet Cutter Machine apply the advanced technique of Germany and England. The machine computer control system apply servo motor and AC trasnducer which are both international of top brand. The conveyer belt apply NITTA from Japan. The pneumatic vibrator apply FINDEVA from Switzerland. The electrical system adopts SCHNEIDER & OMRON. The speed of cutting paper is so fast and stable. Germany precise bearing and cutting knife assure the high cutting precision. The touch screen makes the operation easy. The anti-curve rack assure the paper flate. This machine is the paper processing machine which is very popular in the paper making and printing industry. It can improve the efficiency and benefit of your work.

Product Image:

Main Technical Specification:

| Model | GM-1100/1400/1700/1900 |

| Model of cutting paper | the up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1500(GM-1100)/1800(GM-1400/1700/1900) |

| Max. paper cutting width | 1100/1400/1400/1900mm |

| Cutting length range | 450-1450mm(GM-1100)/450-1600mm (GM-1400/1700/1900) |

| The format of slitting | 2 sheets |

| Cutting precision | Cutting length≤1000mm ±0.5mm; Cutting length>1000mm ± 0.1% |

| Max. cutting speed | 350cuts/min |

| Max. cutting meter speed | 350m/min |

| Max. paper piling height | 1300mm(GM-1100)/1500mm(GM-1400/1700/1900) |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380C/220V/50HZ |

| Gross weight | 11000kgs/13000kgs/15000kgs/17000kgs |

Main Technical Performance

| High precision single knife cutting machine | 1set |

| Paper prismatic automatic adjustment system | 1set |

| Equipment of electrostatic elimination | 1set |

| Middle slitting and waste collection system | 1set |

| Automatic counting and label inserting equipment | 1set |

| Paper transporting equipment | 1set |

| Automatic paper trimming and collecting machine | 1set |

| Electrical controlling system | 1set |

| Driving motor system | 1set |

| Accessory by machine | 1set |

| Doubel arm oil pressure shaftless mill roll stand | 1set |

| Automatic directing and paper tension controller | 1set |

| Equipment of automatic vaccum | 1set |

| Operation system: LCD panel by operator | 1set |

| Main drive system: AC servo motor | 1set |

Packing and Delivery Images:

Prodution Base:

FAQ:

1. What is the order process?

Inquiry for the machine-->offer with technical proposal -->purchasing order-->payment-->production-->delivery-->installation.

2. What is the delivery time for our machine?

Usually within 30 days.

3. What is the payment terms for one order?

30% down payment by T/T. 70% balance byT/T.

4.What is the warranty time for the machine?

One year guarantee.

5. What is the quality control in the company?

We inspect the machine according to blueprint and test the machine before delivery. Our machines are high quality ones.

6. What about packing and delivery?

Normally in wooden case or in full container.

After-sale service:

1. We provide long-term after-sale service.

2. If necessary, we can appoint our technician to install the machine and training your workers with air ticket, visa, accommodation provided by your party. Or you can send your technician to our company to learn techniques.

3. Meanwhile, you can call or e-mail to consult any relevant questions. Or you can communicate online and solve the problems.